- info@alibata.ph

- +63 (49) 554-9360

- Mon-Sat 8:00am-5:00pm

Product Filter

Latest Products

Compaclean

Fully automatic zero drain system. Ideal for cleaning middle to high volume of electronic assemblies. Suitable also for cleaning of soldering pallets and mechanical parts

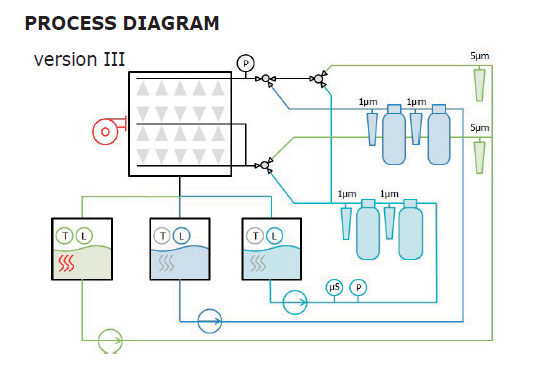

HIGH PRESSURE SPRAY-IN-AIR CLEANING SYSTEM

APPLICATION

- Defluxing, removing activators and resin residues

- Cleaning contamination from handling and board manufacturing

- Cleaning second side misprints on complex assemblies

- Cleaning before conformal coating

- Cleaning of soldering pallets

- Fine degreasing of mechanical parts

Filtration options

- Wash loop is always closed and fully filtrated process that requires regular dosing and periodic drainage when saturated

- Various ways of processing of contaminated rinse loop water

- Rinse loops in CompaCLEAN are flexible by design and meet all process and environmental requirements

Control System

- WIN 7® based, touchscreen, LAN connection

- Complete process traceability available

- Barcode reader for product identification (option)

- Cleaner concentration measuring (option)

- Machine event logging

- Week program for automatic start-up/shut down

- Remote support

- Intuitive control system

- Adaptive rinsing cycle time control

- Three levels password protection

Parameter Specification

- Short cycle time

- High volume batch size

- Zero drain concept

- Small footprint

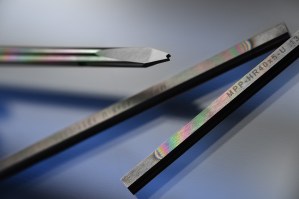

- Uniform spray coverage with high stroke oscillating rack

- Powerful hot air dryer

- Easy operation

- Wide range of standard and customized PCBA fixtures

- Simple yet detailed programming

- Complete datalogging and optional bar code traceability

- Up to 3 fully separated liquid loops

- Very low consumption of chemicals and water

- Outstanding options of water utilization

- Adaptive rinse water quality control by cleanliness threshold

- Automatic chemical concentration control

Videos

0Reviews

There are yet no reviews for this product.

HyperSWASH

HyperSWASH MiniSWASH

MiniSWASH UniCLEAN

UniCLEAN