- info@alibata.ph

- +63 (49) 554-9360

- Mon-Sat 8:00am-5:00pm

Product Filter

Latest Products

IFLEX

The iFlex adds flexible production, matching the industry trend

towards high-mix production. iFlex virtually eliminates product

change-over times to maintain maximum throughput whatever

is on the line. iFlex is a complete series of machines in one.

Three types of modules can be configured in any combination to

meet all production needs and volumes efficiently.

towards high-mix production. iFlex virtually eliminates product

change-over times to maintain maximum throughput whatever

is on the line. iFlex is a complete series of machines in one.

Three types of modules can be configured in any combination to

meet all production needs and volumes efficiently.

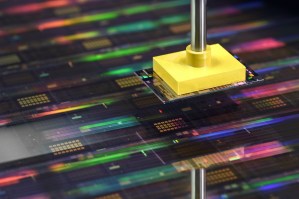

The K&S iFlex is the industry's most flexible modular one-machine concept, available in single-lane or dual-lane. The iFlex machine can be in any combination of any amount of three available modules; scalable in feeder positions, output and/or capabilities, and excels in the four main manufacturing key values, being:

- Quality - Starting at designing the program, until the moment the board leaves the machines, the iFlex uses quality tools and process-driven technologies for the industry's lowest board defect levels of less than 1 dpm!

- Flexibility - Fast in NPI and designed for minimum setup changes and changeovers at batch sizes starting at one PCB - so you can do more jobs a day, and better!

- Efficiency - Technique that is built for constant throughput - for any product, from any job, at any time. Deliver your products always on-time.

- Cost Control - Designed for fast and modular maintenance, low in energy and air consumption. The iFlex is about manufacturing green while saving money, too.

- Constant flow of boards

- In-machine buffer positions eliminate daily line dynamics problems

- Unique fast tray caching for consistent tray speed across all applications

Segmented changeover

- Automatic conveyor adjustment (1)

- Random feeder placement (2)

- Feeder exchange on the fly (3a, 3b)

- Fast trolley exchange (4)

Grippers

- Incl. 10 jaw sets for large gripper range

- Dot codes ensure use of correct gripper

The three available modules are:

- iFlex T4

Chip and IC shooting from 0402M (01005) to 17.5 x 17.5 x 15 mm at 51,000 cph (IPC9850(A)) - iFlex T2

Chip and IC shooting from 0402M (01005) to 45 x 45 x 15 mm at 24,300 cph (IPC9850(A)) - iFlex H1

End-of-line placer placing up to 120 x 52 x 35 mm at 7,500 cph (IPC9850(A))

0Reviews

There are yet no reviews for this product.