- info@alibata.ph

- +63 (49) 554-9360

- Mon-Sat 8:00am-5:00pm

Product Filter

Latest Products

UniCLEAN XLarge

- Fully automatic inline cleaning system

- Ideal for cleaning high volume of electronic assemblies

- Flexible configuration of cleaning technologies

- Ideal for cleaning high volume of electronic assemblies

- Flexible configuration of cleaning technologies

Applications

- Defluxing, removing all kinds of solder residues

- Cleaning of micromechanical components

- Cleaning contamination from handling and board manufacturing, FOD

- Cleaning highly populated electronic assemblies with low standoff components such as BGA, CSP, LGA, MELF etc.

- Cleaning of power electronics

- Cleaning electronic assemblies requiring extra short process time

- Cleaning before conformal coating

- Cleaning before wire bonding

- Cleaning by water based or semi-aqua cleaners

- External filter carts with up to 25l mixbed and 25l active carbon

- Optional double rinse

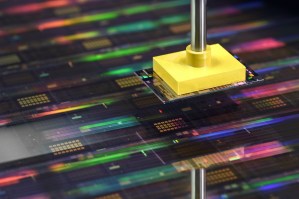

CLEANING WITH UniCLEAN XLarge

- Combination of different cleaning technologies

- Cleaning capacity equivalent to in-line mesh belt systems

- Configuration according to process and capacity needs

- Fully ESD and cleanroom complying

- 7 chambers for various combinations of Wash, Rinse, Dry

- 5-axis robotic transfer for baskets and chamber lids

- Input/output conveyor buffers

- Closed Loop Zero Drain system

- 100% closed loop filtration

- Highly efficient vacuum drying

- Advanced options of water utilization

- Adaptive rinse water quality control

- Various cleaning agent compatibility

- Low consumption of chemicals and water

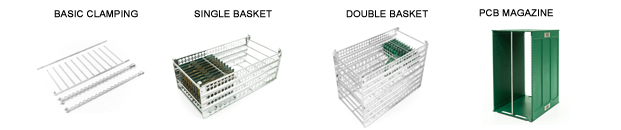

- Standard and customized PCBA fixtures

- Touchscreen interface with Windows OS

- Multilanguage selection

- Statistical process control (SPC)

- Data logging and barcode traceability

- AAD Automatic adaptive dosing of cleaning agent

- Concentration sensor ZESTRON® EYE or KYZEN ANALYST™

XLarge VII

- 7-bath configuration for the highest capacity requirements

- Combination of different cleaning technologies

- Powerful Immersion Spray, Air-Bubbling & Basket Oscillation

- Integrated chemical filters

- All processes are separated to minimize drag over and consumption

- Ideal for zero drain requirements

- Connectable to external water treatment facility

- Cascading of rinse water for maximal water savings

- Highly efficient vacuum dryer

Clamping Option

INTUITIVE TOUCHSCREEN INTERFACE

- All process parameters can be set and operated on machine touchscreen

- Stores up to 100 programs

- Measures and displays all main process parameters

- Control of Time, Temperature, Pressure, Conductivity & Concentration

- Process steps may contain up to 5 substeps for perfect setup

- Fully automatic transloader with programmable drop-off time

- Simple direct operation of transloader available

- Display of real level of liquid in each tank

- Chemical resistant level sensors designed by PBT Works

- Clearly displayed process messages, warnings and errors

- All parameters and messages are saved on a simple log

- Personalised password protection at three access levels

Videos

0Reviews

There are yet no reviews for this product.

Super Swash

Super Swash HyperSWASH

HyperSWASH